Cassonetti.

Shutter boxes

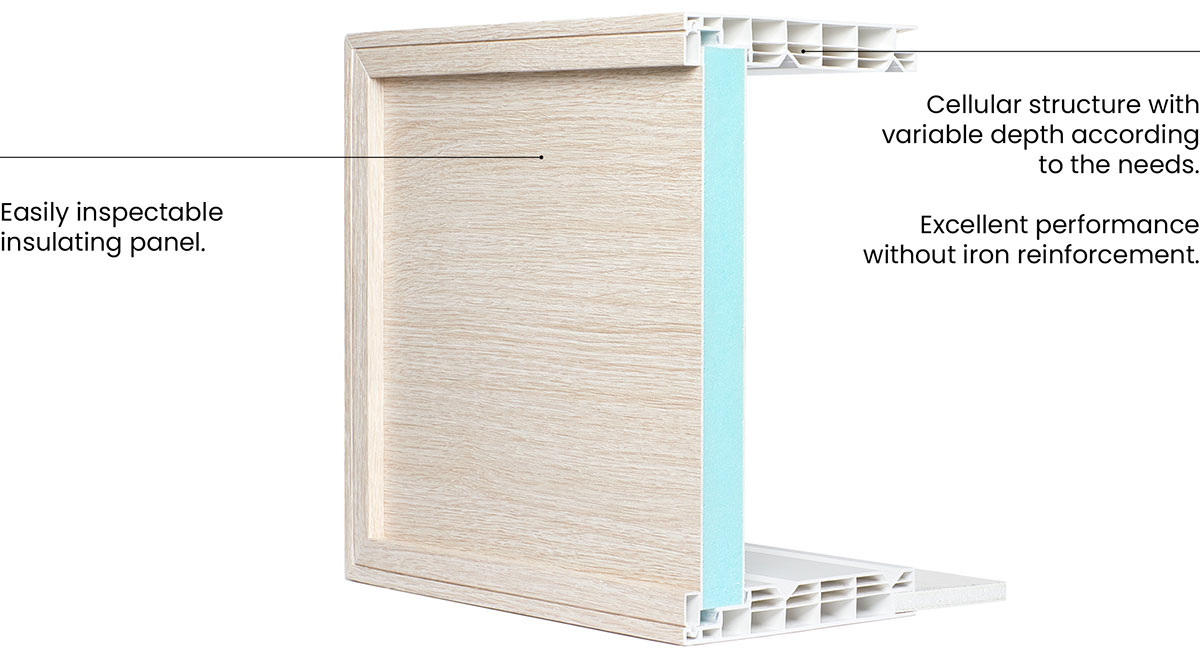

made of PVC.

High performance

without insulation.

Cassonetti

in PVC.

Alte prestazioni

senza coibentazione.

No more drafts.

In a renovation you can replace the windows, choosing the best products available in terms of thermal and acoustic insulation, but many times it is not enough. The shutter box can be the point of passage of cold air or noise inside the apartment. If neglected, the annoying drafts and noise will continue to enter the house.

The shutter box is a fundamental element in a window compartment.

Replacing it is not challenging if you choose the right product. The PVC box I Nobili, thanks to its construction system:

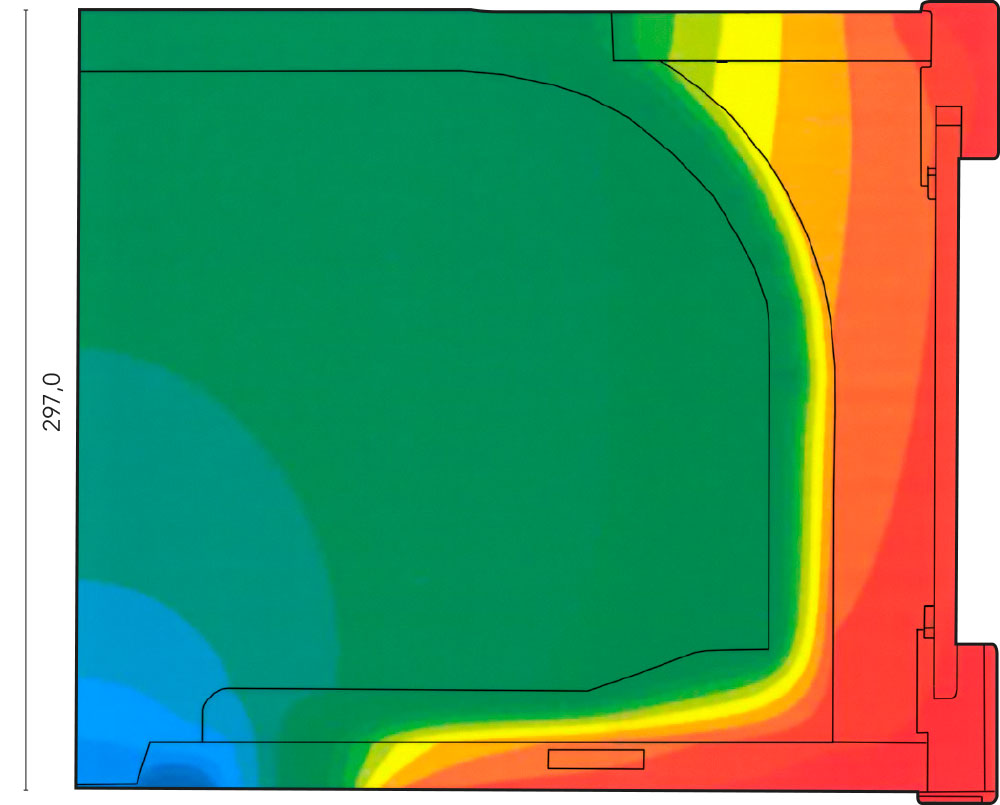

• eliminates any thermal bridge

• reduces the dispersions

• increases thermal and acoustic comfort

• is heat-sealed on joints

Why replace the

shutter box?

The box can be responsible for up to 25% of window hole losses. This involves excessive energy consumption to achieve and maintain the thermal comfort of the environment and, over time, possible problems with mold or condensation.

It's pleasing to look at and easy to clean.

The simple and minimal design is perfectly suited to any environment. The surface does not require special maintenance.

Available in many colors.

To match the box to the fixtures, the color of the walls or furniture.

Installation in minutes.

Assembly is fast and does not require masonry works. It is possible to replace only the box, without being forced to change the frame.

Insulated

shutter box.

NO DRAFT

+ ENERGY EFFICIENCY

IDEAL FOR THE RENOVATION

+ EASE OF INSTALLATION

RENOVATION OF SHUTTER BOX.

THE EASIEST WAY TO SAVE ENERGY.

Insulating the box is easy enough. Of course, you need to replace the windows in order to achieve thermoacoustic comfort inside the house. But often this operation may not be enough. About half of the windows in Italy (the others have shutters) are enriched by roller shutters and their boxes. In Italy, moreover, the container is internal and is often a source of large losses of energy efficiency of an apartment. An efficient solution in this regard is the insulated box, specially developed for the renovation of existing shutter boxes, which is characterized by the exceptional flexibility of assembly and maximum ease of use.

Why renovate the

shutter box?

The insulation of the boxes is essential to ensure the right level of insulation and generally has a very high cost/benefit ratio, both in terms of housing comfort and from the economic point of view, thanks to savings in bills on heating or cooling costs.

increase in living comfort

mold formation reduction

reduced energy losses up to 66%

elimination of air currents

full compliance with recent building requirements regarding energy savings

increased sound insulation up to 6 dB

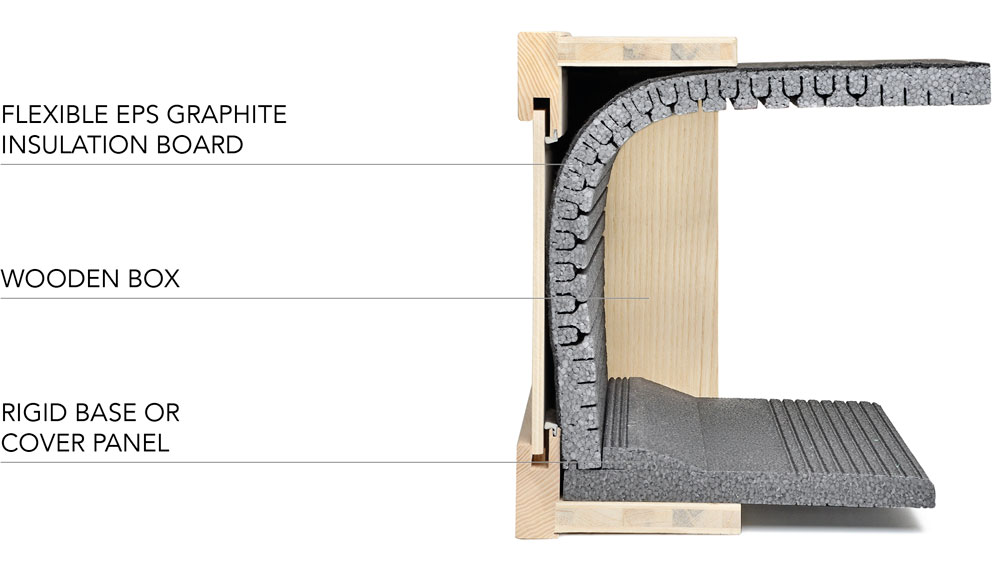

The components

of the system.

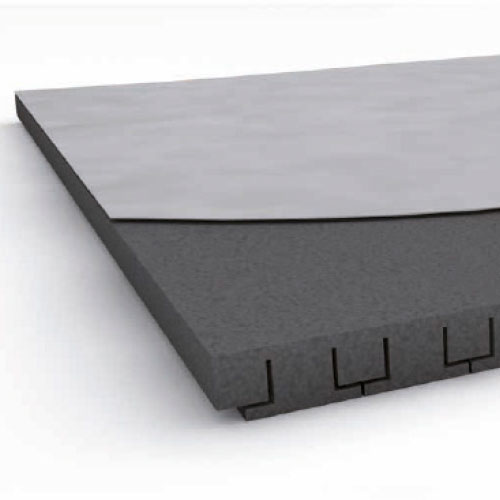

1. FLEXIBLE INSULATION BOARD IN EPS WITH GRAPHITE

The system consists of a grooved panel of Neopor, the latest generation expandable polystyrene capable of ensuring high performance, maximum energy savings and excellent living comfort. Thanks to the presence of graphite particles – which gives it the characteristic silver grey colour – it guarantees exceptional thermal insulation values, offering an insulating capacity almost 20% better than traditional EPS. These particles allow to absorb and reflect infrared, neutralizing the effect due to the radiation of heat that would adversely affect the thermal conductivity. The panel is also sealed with an internal vapor diffusion barrier. It is an easy-to-use material: you can easily cut to size with a cutter. It is free of environmentally harmful chemicals.

| length for insulation | thickness development |

| 1000 x 790 mm | 25 mm |

| 1000 x 500 mm | 25 mm |

2. RIGID BASE FOR COVER PANEL

The rigid base for the cover panel made of Neopor® (thermal conductivity class 032) is supplied with a width of 240 mm.

Thanks to the predefined cutting points, the cut to size in the desired width is easily and the insulation thickness in the joint zone is adjusted.

| length | 1000 mm |

| width | 150 – 240 mm* |

| insulation thickness | 20 mm |

*easy adjustment thanks to predefined cutting points

| U-factor | delta T | lenght |

| 0.76 W/m2k | 20.0 C | 304 mm |