Certifications and

guarantees.

The windows and shutters are built with care and materials designed to last. Thanks to the constant commitment and the experience gained, we have reached high quality standards, which guarantee the operation over time of the windows. We test, certify and guarantee all the lines, ensuring the total quality and safety of the products.

Quality Management System certified according to UNI EN ISO 9001:2015

ISO 9001 defines the requirements of the quality management system in the company.

Each activity, each process, are aimed at determining the maximum satisfaction of the final customer. The Customer Satisfaction system and its cyclical monitoring are fundamental. For this reason, all areas of the business organization are actively involved: management, human resources, design, sales, procurement, production, installation, marketing, commercial and after-sales.

To obtain certification, it is important to define the mission and the vision, integrating them to the maximum in the business processes. The quality management system is a support to the achievement of all objectives.

The legislation is updated periodically.

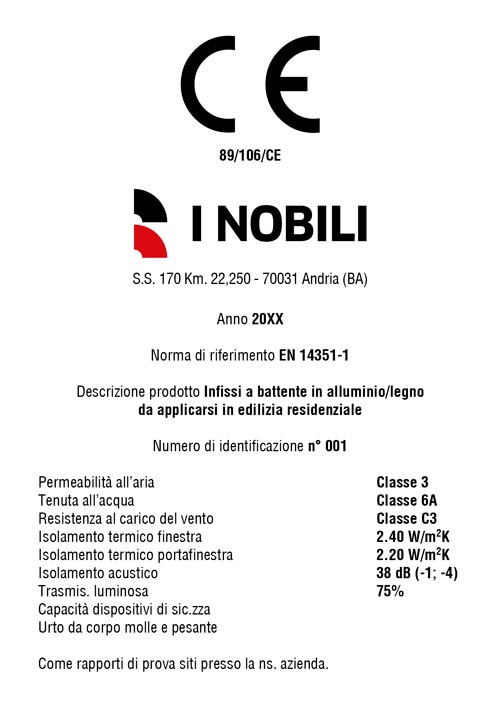

CE marking.

All products of I NOBILI has CE Marking. I NOBILI releases the certificate of conformity in accordance with UNI EN 14351-1 and UNI EN 13659, in application of the European Directive 89/106/EC.

Conscious purchase

responsible production.

I NOBILI HAS CE MARKING

From 1 February 2010, windows, French windows and exterior pedestrian doors can only be marketed and sold in the European Union if they have been CE marked.

CE marking is a declaration of conformity of the frame to the essential requirements of the European Directive 89/106 (Construction Products) and to the product standard UNI EN 14351-1:2006.

The essential requirements are:

- energy saving and heat insulation;

- mechanical strength and stability;

- sound protection;

- safety in use;

- safety in case of fire;

- hygiene, health and environment.

The manufacturer can mark their windows only after:

- have received the results of the tests performed on the sample frames (ITT tests);

- have implemented the Production Control Plan (FPC), to ensure compliance of all the frames produced with the characteristics attested by tests and verifications calculated by the Notified Laboratory.

The results of the ITT (Initial Type Test) tests on sample frames can be obtained in three ways:

- directly, choosing the type and dimensions of the windows to be tested at a Notified Laboratory;

- through Cascading, using test reports made to the supplier of profiles or accessories and provided to him for the use permitted by a contract between the parties;

- via Shared mode, using the test report shared by several manufacturers and headed to one of them.

THE PURPOSES

Make the consumer aware of what he buys.

Make the producer aware and responsible for what he produces and markets.

The EC label indicates:

- manufacturer’s data;

- the description of the product;

- the values of the performance characteristics of the product.

On request, the Declaration of Conformity of the frame to the reference standards and directives is also provided.

THE PERFORMANCE CHARACTERISTICS

- Thermal transmittance

- Resistance to wind load

- Sound insulation

- Air permeability

- Watertightness

- Impact resistance

- Bearing capacity of safety devices

- Radiative properties of glassware

VOC certifications.

I NOBILI guarantees its PVC frames with VOC certification according to D.M. 16 January 2004 n. 44. This certification attests that windows and French windows do not emit volatile organic compounds harmful to health.

Indoor air quality is an extremely important issue for the health of citizens, because the health risks caused by exposure to indoor air pollution can also be higher than those caused by exposure to outdoor air pollution.

People spend about 90% of their time inside buildings. Many substances tend to be slowly released over time within the environment in which the finished products are placed. I NOBILI guarantees its PVC frames with VOC certification according to D.M. 16 January 2004 n. 44. Compounds that can be emitted from materials are normally classified as:

COV: volatile organic compounds;

VVOC: very volatile organic compounds;

SVOC: Semi-volatile organic compounds that may be particularly persistent by being released slowly over time.

The European Union has published the EU regulation n. 305/2011 that includes internal emissions among the basic requirements for building materials. Ensuring a healthy and comfortable climate in everyday living or working environments, in compliance with the highest standards of energy efficiency, is, therefore, of utmost importance. Nevertheless, manufacturers of building materials must ensure that their products cannot harm the users of buildings.

The fundamental requirement n. 3 of the Construction Products Regulation provides that the works are designed and built in such a way as not to pose a threat to the hygiene or health and safety of their occupants. To meet this objective, the European Commission has commissioned CEN to develop a harmonised test method to measure the emissions of VOC (Volatile Organic Compounds) and SVOC (Semi-volatile Organic Compounds) of construction products.